Exploring Safety Vinyl Flooring Options: Coved, Sit-On, and Set-In Skirtings, Weld Techniques, and Hygiene Factors

- Branew Flooring

- Sep 17, 2025

- 4 min read

Safety vinyl flooring has surged in popularity across various sectors. Its durability, low maintenance, and safety features make it the flooring of choice for many. This post dives into skirting options like coved, sit-on, and set-in skirtings. We will also discuss welding techniques and hygiene factors while outlining the top locations to install safety vinyl flooring.

Understanding Safety Vinyl Flooring

Safety vinyl flooring is designed to minimise slips, making it perfect for high-traffic areas. You'll find it in healthcare facilities, schools, care homes, gymnasiums, and commercial kitchens, where both safety and cleanliness are essentials.

It's manufactured with a textured surface that provides enhanced grip. This feature is crucial in environments where spills can occur frequently—studies show that slip-resistant flooring can reduce accidents by up to 70%. Furthermore, the available designs, including wood and stone effects and various colours, provide the flexibility to maintain a professional appearance while ensuring functionality.

Skirting Options: Coved, Sit-On, and Set-In

The right skirting can significantly impact the finish and hygiene of safety vinyl flooring. Here are three primary types of skirtings, along with their benefits and typical applications.

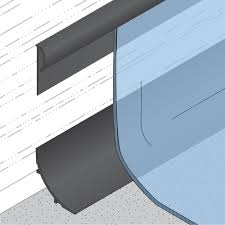

Coved Skirtings

Coved skirtings, also known as Cap and Cove skirting, is a specialist flooring finish used primarily in hygiene-critical environments. It involves continuing the floor covering up the wall at the junction between floor and wall, creating a seamless, curved transition. This is achieved using two components: a cove former, which is a curved profile fitted at the base of the wall to support the flooring as it bends upward, and a capping strip, which seals the top edge of the flooring where it meets the wall surface.

This method eliminates sharp corners and exposed edges, making cleaning easier and reducing the risk of dirt or bacteria buildup. It also provides a sleek, professional look and ensures compliance with hygiene regulations in wet-cleaned or sanitised areas. Cap and cove skirting is often specified in healthcare and food preparation sectors for its durability, low maintenance, and infection control benefits.

Sit-On Skirtings

Sit-on skirting is a flexible PVC trim used in flooring installations to cover the junction between the wall and the floor. It’s installed on top of the floor covering—hence the name “sit-on”.

This type of skirting provides a clean, professional finish while protecting walls from scuffs and moisture. It’s quick to install, low maintenance, and ideal for hard floor coverings like vinyl or safety flooring. Compared to set-in skirting, which is welded into the flooring and better suited for wet-cleaned areas, sit-on skirting offers a practical solution for dry environments where speed and visual consistency are priorities.

Set-In Skirtings

Set-in skirting is a PVC trim where the skirting is welded directly to the floor covering, typically vinyl or linoleum. This creates a sealed, impervious joint between the wall and the floor, making it ideal for environments that require frequent wet cleaning or strict hygiene standards—such as hospitals, laboratories, and food preparation areas.

Unlike sit-on skirting, which is applied on top of the flooring after installation, set-in skirting is fitted before the floor covering is laid. The flooring material is then welded to the skirting, forming a continuous, easy-to-clean surface that prevents dirt and bacteria from accumulating at the junction. This makes it a preferred choice for compliance with infection control and sanitation regulations.

Importance of Weld Techniques and Hygiene Factors

Welding plays a critical role in the installation of safety vinyl flooring, especially in areas demanding excellent hygiene. By fusing seams of the vinyl flooring, welding creates a continuous surface that eliminates spaces where dirt and bacteria thrive.

There are two primary welding techniques: hot and cold welding. Hot welding uses heat to melt and bond the edges of the vinyl, providing a strong hold, while cold welding uses an adhesive. Both techniques can achieve a hygienic finish. However, hot welding tends to be preferred in environments where cleanliness is essential.

Welded seams can significantly enhance the durability of the flooring. A properly welded floor can endure heavy foot traffic and resist wear, offering a long-lasting flooring solution for various applications.

Best Locations for Safety Vinyl Flooring Installation

Safety vinyl flooring is versatile and can be installed in diverse environments. Here are a few locations where safety vinyl excels:

Healthcare Facilities

In hospitals and clinics, safety vinyl flooring is vital to maintaining a clean and safe environment. Its slip-resistant surface prevents accidents, while its seamless design reduces infection risks. In fact, hospitals that use safety vinyl have reported a 25% decrease in floor-related injuries.

Educational Institutions

Schools and nurseries greatly benefit from safety vinyl flooring. It's durable, easy to maintain and can withstand heavy foot traffic. Moreover, it simplifies cleaning, which is essential in classrooms and play areas. Schools using this type of flooring have found it helps lower cleaning costs by about 20%.

Commercial Kitchens

Safety vinyl flooring is essential in commercial kitchens. Its slip-resistant surface helps prevent accidents, while the welded seams allow for quick and effective clean up of spills. This flooring not only enhances safety but also contributes to maintaining a hygienic kitchen environment.

Care and Residential Homes

Care and residential homes are other places that benefit from safety vinyl flooring. The variety of available designs provides plenty of aesthetic options, while the safety features ensure a secure and comfortable living environment for residents. Care home operators have also noted that proper flooring can enhance resident confidence and comfort, leading to improved overall satisfaction.

Retail Spaces

Retail environments also benefit from safety vinyl flooring. The variety of available designs provides plenty of aesthetic options, while the safety features ensure a secure and comfortable shopping experience for customers. Retailers have also noted that proper flooring can improve customer confidence, leading to increased sales.

Final Thoughts

Investing in safety vinyl flooring is more than just about looks; it plays a critical role in creating a safe and hygienic space. With options like coved, sit-on, and set-in skirtings and effective welding techniques, you can tailor your flooring to meet both functional and aesthetic needs.

Understanding your options and their benefits can help you choose the right safety vinyl flooring for your environment. Whether it’s a healthcare facility, school, commercial kitchen, or retail space, this flooring solution will ensure that safety and cleanliness remain top priorities for everyone.

If you need further details about safety vinyl or would like to request an estimate, feel free to reach out to Branew Flooring at any time. We’re here to help and give you the best advice about all your flooring requirements!

Comments